Understanding Ribbing in Metal Panels: How It Improves Strength and Longevity

Metal panels are widely used in the construction of roofing, siding, and other structural applications because of their versatility and durability. One key feature that enhances their performance is ribbing, which adds aesthetic appeal and boosts strength and longevity.

What exactly is ribbing, and how does it improve strength and longevity? We’ll explore how this unique feature makes metal panels appealing for various construction projects.

What is Ribbing in Metal Panels?

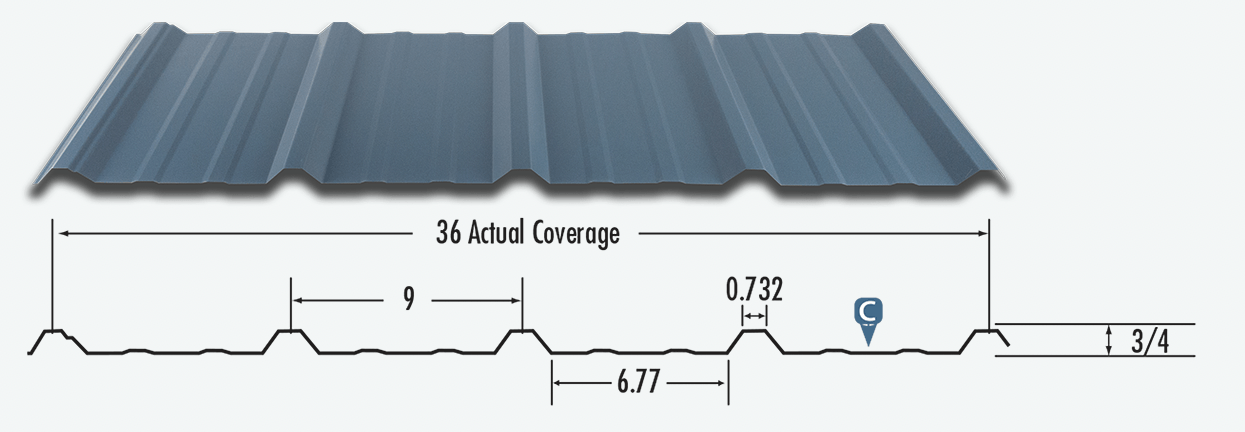

Ribbing refers to the repetitive patterns or grooves incorporated into the design of metal panels. These ribs can take various forms, such as corrugated or V-shaped designs, and are engineered to serve both functional and aesthetic purposes.

The primary purpose of ribbing is to reinforce the structural integrity of the panel. Ribbing reduces the tendency for the material to bend or sag under weight, improving its load-bearing capacity by adding depth and contour to what would otherwise be a flat surface.

How Ribbing Enhances Spanning Strength

Ribbed panels strike a hard-to-find balance between flexibility and rigidity. Being able to flex slightly under pressure allows metal panels to avoid cracking or warping — making ribbed panels perfect for areas with heavy snow or high winds.

Another key advantage of ribbed metal panels is their ability to improve spanning strength, allowing the panel to support heavier loads over wider areas. This benefit is made possible due to the efficient load distribution of how ribs are designed, which distributes pressure more evenly across the surface entirely.

How Do They Stack Up to Flat Panels?

Ribbed metal panels demonstrate vastly superior spanning strength compared to flat panels. Flat panels lack the reinforced structure ribs provide, making them more susceptible to bending and deformation under load.

Ribbed panels are designed to maximize strength without adding excessive weight or material thickness. The design of ribs changes how weight is distributed across the material, allowing the same amount of raw materials to handle more weight and last longer.

Ribbing for Long-Term Durability

Ribbing plays a crucial role in ensuring the long-term durability of metal panels. Grooves create natural channels for water runoff, reducing the risk of pooling that could lead to corrosion or leaks. This feature enhances the weather resistance of ribbed panels, making them highly effective for outdoor applications.

Additionally, ribbed panels exhibit greater longevity in large-scale applications, such as warehouses, barns, or commercial buildings. Their enhanced strength reduces the need for frequent repairs or replacements, ensuring that structures remain functional and cost-effective over time.

Invest in Quality Ribbed Metal for Your Next Project

Ribbing in metal panels is far more than a design feature — it’s a functional enhancement that significantly improves strength, durability, and weather resistance. Construction projects requiring reliable, long-lasting materials can greatly benefit from ribbed metal panels that provide strength and longevity for years.

Are you using the right materials for your construction projects?

Contact us today to learn more about ensuring you’re using the right materials that provide strength and longevity.